Project Overview

Microfabricated Air-Core Inductors

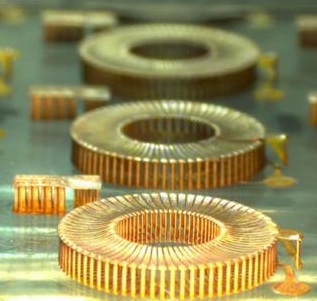

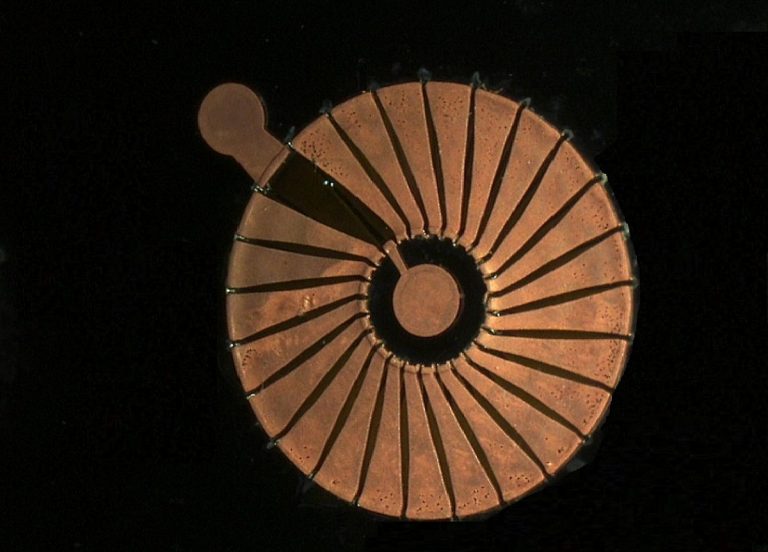

Air-core magnetics offer the advantage of avoiding the high losses most ferromagnetic materials contribute at very high frequencies. Although some air-core designs have high winding losses and produce external magnetic fields that are a liability for electromagnetic interference and induced power losses in nearby materials, toroidal configurations can be self shielding and can be designed for low losses. We are working towards two approaches: 1. Microfabricated air-core inductors on low-loss substrates; and 2. Silicon-embedded inductors. The collage shows various 3-D microfabricated inductors with inductances ranging from 0.05 to 0.7 uH. The inductor designs are compatible with flip-chip bonding technologies for integrated PowerSoc. In collaboration with MIT, Dartmouth college, and UPenn, we are currently evaluating these inductors in high-voltage high-frequency circuits.

Collaborations: MIT, Dartmouth College, University of Pennsylvania

Sponsor: ARPA-e

Publications

- X. Yu, M. Kim, F. Herrault, C.-H. Ji, J. Kim, and M.G. Allen, "Silicon-embedding approaches to 3-D toroidal inductor fabrication," Journal of Microelectromechanical Systems, in press.

- M. Araghchini, J. Chen, V. Doan-Nguyen, D.V. Harburg, D. Jin, J. Kim, M. Kim, S. Lim, B. Lu, D. Piedra, J. Qiu, J. Ranson, M. Sun, X. Yu, H. Yun, M.G. Allen, J.A. del Alamo, G. DesGroseilliers, F. Herrault, J.H. Lang, C.G. Levey, C.B. Murray, D. Otten, T. Palacios, D.J. Perreault, and C.R. Sullivan, "A technology overview of the powerchip development program," Transactions on Power Electronics,v 28, n 9, p 4182-4201, Sept. 2013. (PDF)

- J.K. Kim, F. Herrault, X. Yu, M. Kim, R.H. Shafer, and M.G. Allen, "Microfabrication of air core inductors with metal-encapsulated polymer vias," Journal of Micromechanics and Microengineering, v 23, n 3, p 035006 (7 pp.), March 2013. (PDF)

- J.K. Kim, F. Herrault, X. Yu, and M.G. Allen, "Microfabrication of air-core toroidal inductor with very high aspect ratio metal-encapsulated polymer vias," PowerMEMS 2012, p 30-33, Dec. 2012. (PDF)

- X. Yu, M. Araghchini, F. Herrault, J.K. Kim. J.H. Lang, and M.G. Allen, "Fabrication, modeling and performance analysis of silicon-embedded 3-D toroidal inductors," PowerMEMS 2012, p 58-61, Dec. 2012. (PDF)

- M. Araghchini, M. Kim, X. Yu, F. Herrault, M.G. Allen, and J.H. Lang, "Modeling and measured verification of loss in MEMS toroidal inductors," IEEE Energy Conversion Congress and Exposition (ECCE), p 3293-3300, Sept. 2012. (PDF)

- D.V. Harburg, X. Yu, F. Herrault, C.G. Levey, M.G. Allen, and C.R. Sullivan, "Micro-fabricated thin-film inductors for on-chip power conversion," 2012 7th International Conference on Integrated Power Electronics Systems (CIPS), p. 6ff, March 2012. (PDF)

- X. Yu, M.S. Kim, F. Herrault, C.-H. Ji, J.K. Kim, and M.G. Allen, "Silicon-embedded 3D toroidal air-core inductor with through-wafer interconnect for on-chip integration," IEEE International Conference on Micro Electro Mechanical Systems (MEMS), p 325-328, Jan. 2012. (PDF)

- Y.-K. Yoon, J.-W. Park, and M.G. Allen, "Polymer-core conductor approaches for RF MEMS," Journal of Microelectromechanical Systems, v. 14, n. 5, Oct, 2005. (PDF)

WEISS HTML5 TEMPLATE BY THEMEPRINCE © 2012 - ALL RIGHTS RESERVED!

All information in these pages is copyrighted. Copyright © 2013 by the School of Electrical and Computer Engineering, Georgia Institute of Technology. Disclaimer